Professional Manufacture of Gearless-design Diaphragm Pressure Gauges

Choosing qualified suppliers、assembly part inspection、strict quality assurance to the whole production process、final quality control to every single pressure gauge, the entire control procedure reaches to superior quality.

Please click the following link. This video will show you how Chin Ray concentrate on producing diaphragm pressure gauges every single day.

Video introducing Chin Ray

Over these years, Chin Ray acquires customers' confidence and thanks for our business partners' faithful support from USA、EU、Japan worldwide, Chin Ray creates annual sales volume growing to millions pieces of pressure gauges.

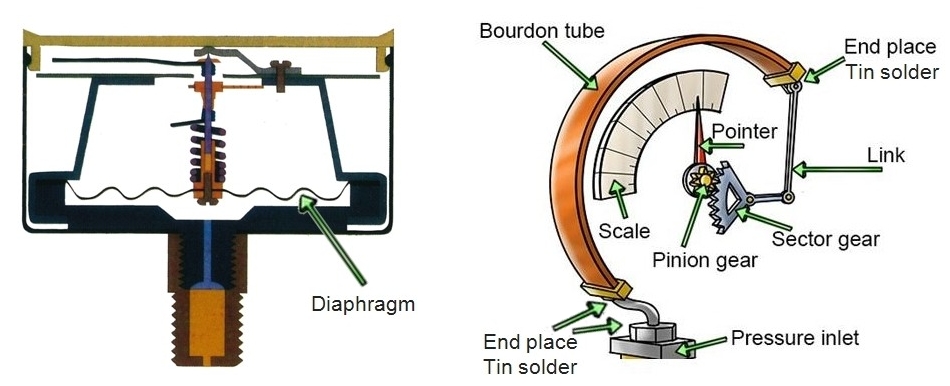

After replaced Bourdon Tube gauges with innovated diaphragm structure, there's without pinion(gears) inside diaphragm pressure gauge. Due to this patented invention, diaphragm pressure gauge is more sudden pressure endurable, more shock-resistant, more accurate and extending its service life.

In 2015, Chin Ray officially launches 3 IN 1 (pressure measure, inflation and deflation) tire inflator.

This tire inflator is assembled with diaphragm pressure gauge. Even though dropping down tire inflator by accident, diaphragm structure keeps precise accuracy maintained. This strength supports Chin Ray customers with a tremendous sales in Japan, Europe & America.

Currently, Chin Ray has offered a wide range of gearless-design diaphragm pressure gauges to tire pressure gauges, mini air compressor, tire inflator, cylinder diagnostic tools, floor pump, pneumatic hand tools, medical facility, plump & pipe test gauges for building construction… etc.

After successfully accumulating valuable experience in producing pressure gauges, Chin Ray has built a reputation in Automotive Aftermarket, Bike, Racing, Truck, Medical, Plumbing, Piping & Chemical industries. We now closely co-operate with lots of global well-known suppliers such as Stanley Black & Decker、SKF LINCOLN、Harley Davidson、Spalding、Molten.

Our mission is to contribute ourselves to high-level pressure gauges with precise accuracy and stable quality, suitable and fit to a variety of tools & equipment. Chin Ray always aims for long-term partnership with our customers and chase for win-win future.

Features of Gearless-design Diaphragm Pressure Gauge

● Sudden pressure or pulse pressure endurable

● Shock-resistant : the following video displays Chin Ray tire inflator passing drop test from height 1M.

<<Drop Test Video of Hafner Tire Inflator>>

● Accuracy complying with ANSI/ASME standard B40.100 & EN837-1

● QA team to ensure product quality

● R&D team for consistent product innovation and upgrade.

Comparison of Hafner Diaphragm & Bourdon tube pressure gauges

| NO | Comparison | Hafner Diaphragm pressure gauge | Bourdon tube pressure gauges |

| 1 | Sudden pressure endurable |

With gearless diaphragm design, Hafner pressure gauges are endurable when sudden air inflates (e.g. 0psi to 100psi). Users don’t need to spend extra time & additional cost to fill in liquid(glycerin) inside gauges, Pointer of Hafner gauge moves smoothly to assist user to read scale correctly |

Bourdon Tube gauge is gear-drive connecting to dial reading. When sudden pressure is charged to the gauge, pinion shifting(gears out of path) occurred easily if users do not fill in liquid(glycerin) to secure the gears in path of movement. Invisible cost increases. |

| 2 | Shock-resistance | Strength of gearless gauge structure and forming with steel parts prevent diaphragm gauge twisted from force. When users drop Hafner pressure gauge on the ground by accident, inner structure is completed and still gives correct reading for measurement. | Both ends of Bourdon Tube gauge are Tin solder with gear link & pressure inlet. Since Tin is soft metal, it’s easily twisted by force and affects scale reading. |

| 3 | Pointer movement | Pointer is under good control, moving on stably. This characteristic is particularly obvious in vacuum gauge (e.g. medical suction…) or pump equipment (e.g. air compressor or floor pump…). | Because of gap existed between pinions, pointer vibrates easily especially air inlets in vacuum suction or pump equipment. |

| 4 | Accuracy | Pressure tolerance and variance of diaphragm are linear. Accuracy adjustment is simple. Without gear gap, accuracy is permanent and complying with standard ANSI/ASME B40.100 (+/-3%~+/-2%~+/-3%) or EN 837-3(+/-2.5% F.S.) | There’s gap between gears inside Bourdon tube gauge. It causes accuracy error so needs overall quality inspection by labors to control yield rate. |

| 5 | Anti-over pressure | Diaphragm pressure gauge is able to be assembled anti-over pressure device. This device will help to protect gauge lifetime, ensure precise measure function & avoid inner structure broken when users inflate air over pressure by accident. PS : Optional specification. Please mention in your inquiry message. |

Once over pressure happened accidently by users, gears/pinions in Bordon tube structure will immediately damaged and caused measure function failure. From gauge surface, you’ll notice the pointer is not move back to zero pin which proves that gauge is over pressure. |

| 6 | Corrosion-proof | When pressure gauge is located in the place surrounded with corrosion substance or pressure media is related to corrosion, we can provide specific parts corrosion-proof in gauge production. Additional cost is not much. PS : Optional specification. Please mention in your inquiry message. |

For environment around corrosion substance or pressure media is corrosive, Bourdon Gauge is assemble one more alloy or stainless plate(also called diaphragm) in bottom of gauge adaptor. This plate is external and additional cost is higher than Hafner diaphragm pressure gauge. |

Milestone

-

1993

Headquarter『Chin Ray Industry Ltd』& its first factory established

-

1993

Brand『Hafner』set up

-

1998

The first factory expansion and relocated in Huzinei, Chiayi city

-

2005

Officially promote 2 In 1 tire pressure gauges & thread depth

-

2007

Acquire Certificate of ISO-9001

-

2010

The second factory expansion and relocated in Shuishang, Chiayi county

-

2012

Acquire Certificate of CE

-

2016

Obtain Certificate EN12645

-

2016

3 In 1 Tire Inflator debut

-

2018

Renew Certificate of ISO-9001-2015 & CE

-

2019

Pass through certificate of TTQS for employee on-duty training & career development